Industrial Plumbing Systems: Understanding the Basics for Efficient Operations

Explore the essential elements of industrial plumbing systems for optimal efficiency, maintenance, and safety.

In the world of plumbing, where every twist of a pipe and every valve adjustment can make a significant difference, achieving operational efficiency is paramount. This article will discuss the fundamental aspects of industrial plumbing systems , shedding light on their components, maintenance strategies, common challenges, water conservation techniques, safety measures, and much more.

Industrial plumbing isn’t just about pipes and fittings; it’s a symphony of interconnected components working harmoniously to ensure the seamless flow of liquids and gases. Together, we’ll navigate the intricate details of industrial plumbing systems, unravelling their complexities and offering insights from years of hands-on experience and a deep understanding of the field.

Whether you’re a facility manager looking to optimise your plumbing setup, an aspiring plumber eager to broaden your expertise, or a business owner keen on enhancing operational efficiency, this comprehensive guide is tailored to meet your needs.

So, buckle up and prepare to dive into industrial plumbing . From the nuts and bolts to the most intricate design principles, we’re here to equip you with the knowledge you need to take your plumbing operations to the next level.

Components of Industrial Plumbing Systems

Picture an industrial plumbing system as a finely tuned orchestra, where each instrument plays a distinct role in creating a harmonious melody. Similarly, industrial plumbing systems have various components, each with a specific purpose. Let’s delve into some of the critical components that constitute these systems:

- Pipes and Fittings : They are made of various materials, including PVC, steel, and copper, each chosen based on the intended use and environmental factors. Fittings like elbows and tees ensure proper connections and directional changes.

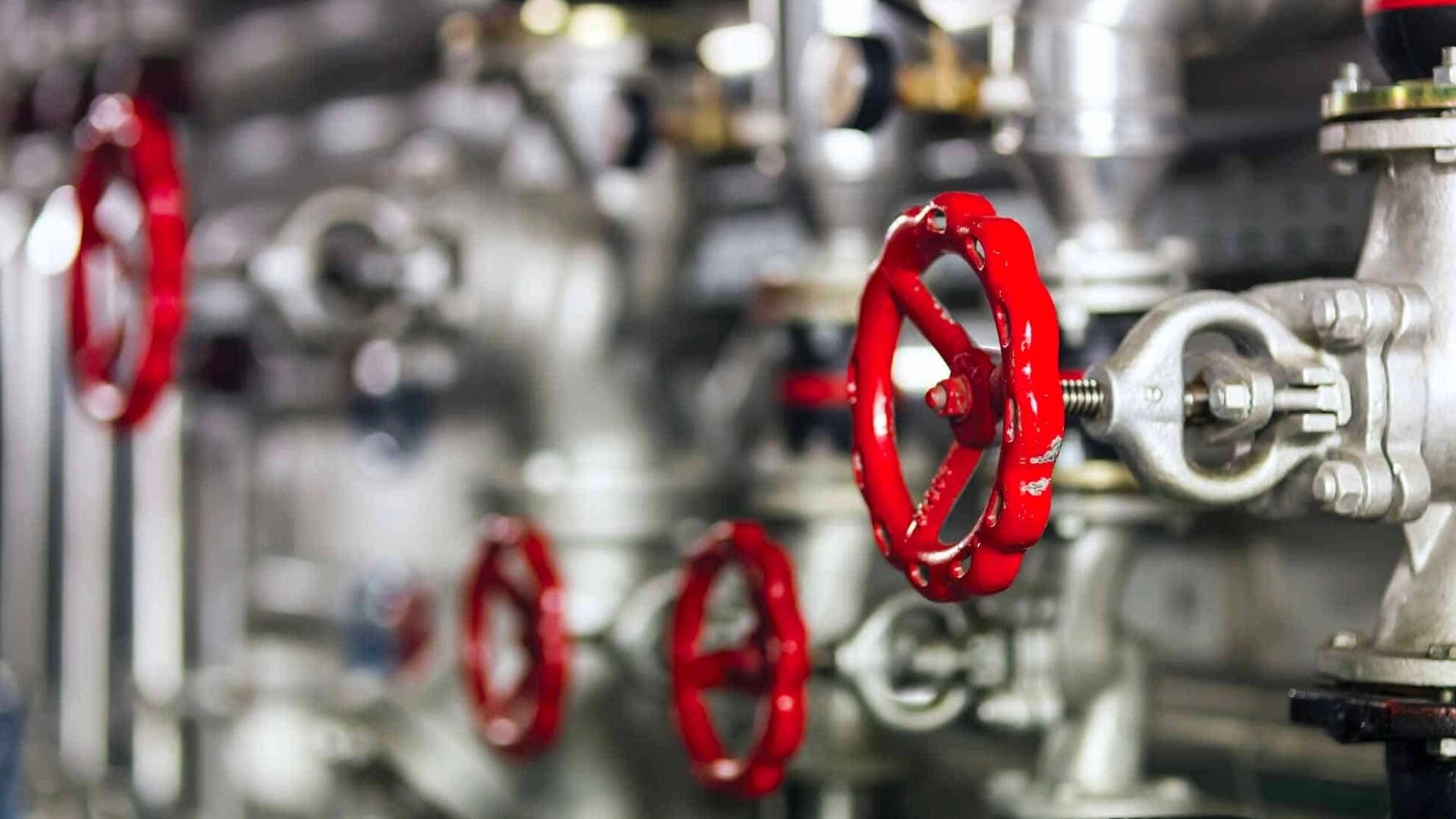

- Valves : These control mechanisms regulate the flow of fluids through the system. From gate valves that offer on/off control to ball valves for quick shut-offs, each type serves a distinct purpose in managing flow and pressure.

- Pumps : Industrial operations often require fluid movement against gravity or over long distances. Pumps provide the force to push liquids through the system, ensuring efficient distribution.

- Water Heaters and Boilers : In facilities requiring hot water , water heaters and boilers play a pivotal role. These devices heat water to specific temperatures, ensuring a constant supply for various processes.

- Backflow Preventers : These crucial devices prevent the reverse flow of contaminants into the water supply , safeguarding public health and maintaining water quality.

- Pressure Regulators : Maintaining consistent pressure within the plumbing system is essential for optimal operation. Pressure regulators ensure water or gases are delivered at the desired pressure levels.

Maintenance Strategies for Industrial Plumbing

Maintaining the peak performance of your industrial plumbing system requires more than just reactive fixes; it demands a comprehensive approach that identifies potential issues before they escalate. Industrial plumbing maintenance starts with regular inspections. A proactive eye can catch minor leaks , corrosion, or signs of wear and tear before they become major concerns.

You can address issues at their onset through consistent checks, preventing costly downtime and repairs. Scheduled servicing is another cornerstone of adequate maintenance.

Plan routine maintenance sessions where trained technicians can fine-tune your system, ensure valves function correctly, pumps deliver optimal flow, and all components are in top shape.

Consider incorporating predictive maintenance techniques. Leveraging data and advanced technology, you can predict when specific components might fail based on their performance trends. This allows for targeted replacements or repairs, minimising disruptions.

Keeping an eye on water quality is super important, especially for businesses that need their water to be just right. Checking the water for its acid level (pH), any nasties (contaminants), and bits and pieces that shouldn’t be there (minerals) can stop yucky stuff like scale and rust from messing up how things work.

It’s a great idea to ensure the folks who look after your water systems know their stuff. When your maintenance crew is up to scratch, they’re your best bet to stop any troubles before they start. Keep giving them the latest training so they’re clued in on new ways and the best way to do their job.

Writing down what you do is super crucial, too. Keep a good record of all the check-ups and fixes and when you swap out parts . This record is like a health check history for your water systems, which can help you make intelligent choices later on.

Getting licensed and experienced plumbers is part of the whole deal. They’re essential for making sure everything is working as it should. These pros know all about the vital bits (critical components) and how to keep them in good nick (proper functioning). Plus, they can handle the big jobs essential for keeping your water running smoothly.

Common Challenges in Industrial Plumbing

Here are some of the common hurdles that industries often encounter in their plumbing systems:

- Corrosion and Rust : Certain fluids’ corrosive nature, coupled with exposure to moisture, can lead to corrosion of pipes and fittings . This compromises the integrity of the system and affects water quality.

- Scaling and Buildup : Minerals present in water can accumulate over time, leading to scale build-up in pipes and equipment. This reduces flow efficiency and can even cause blockages .

- Leaks and Drips : Even a tiny leak can lead to significant water wastage and potential property damage. Identifying leaks promptly through regular inspections and investing in reliable seals and gaskets can prevent wasteful leaks.

- Pressure Fluctuations : Inconsistent pressure can disrupt operations and damage equipment. Pressure regulators and regular system checks ensure the pressure remains within the desired range, optimising performance.

- Temperature Variations : Industries often require specific water temperatures for processes . Inadequate temperature control can affect product quality and efficiency.

- Blockages and Clogs : Foreign objects, debris, and sediment can block pipes and equipment. Regular cleaning, filtration systems, and proper waste disposal practices are essential to prevent clogs .

- Energy Inefficiency : Inefficient plumbing systems can consume excessive energy, resulting in higher operational costs. Implementing energy-efficient components like pumps and water heaters can lead to substantial savings.

Industrial Plumbing System Design Principles

Crafting an efficient industrial plumbing system requires a deep understanding of design principles. Begin with a thorough needs assessment. Understand fluids, temperatures, and pressures to design a system tailored to your requirements.

Fluid flow is central; ensure smooth flow by strategically sizing pipes and incorporating efficient components.

Build redundancy and reliability to ensure operational continuity. Design alternate routes and backup systems to address unexpected challenges. Prioritise accessibility for maintenance.

Components should be easy to inspect, repair, and replace without disrupting operations. Embrace sustainability by capturing rainwater and implementing water-saving fixtures to conserve resources and cut costs.

Plan for future expansion by designing with scalability, allowing seamless integration of new processes or equipment. Adhere to industry compliance and codes to prevent legal and safety issues.

Connect with Service First

Industrial plumbing is a symphony of efficiency, sustainability, and resilience, a balance that Service First is uniquely poised to provide.

Our commitment extends beyond words—it’s rooted in understanding your operational nuances, creating tailor-made solutions, and being a reliable partner you can trust. Whether you seek consultation, quotes, or practical guidance, we support you at every step.

Remember, each aspect of your plumbing system contributes to the overall performance. Every choice you make, from initial design to ongoing maintenance, from safety protocols to cost considerations, shapes your success trajectory.

Connecting with Service First opens the door to a plumbing future of efficiency, innovation, and excellence. Let’s work together to build plumbing solutions that are not just practical but exceptional.

, and let’s build a better plumbing future together.